100 kHz control for highest precision

- Active resonance suppression

- Highest control stiffness

- Best control quality - minimum errors

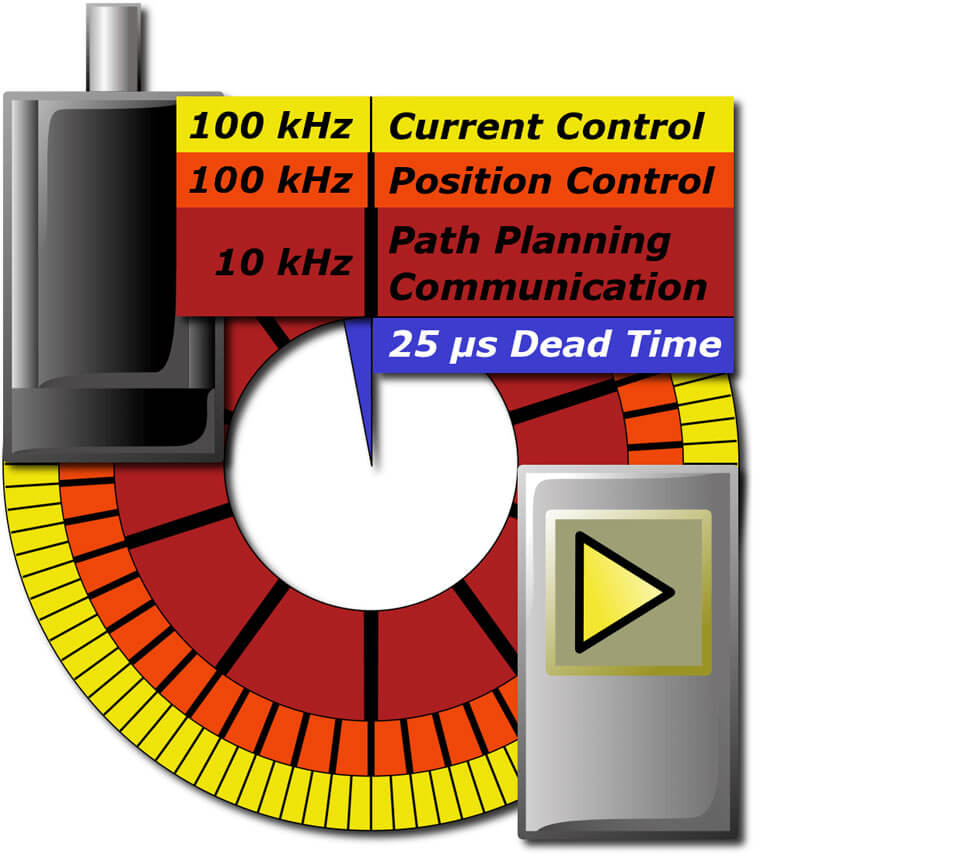

Triamec servo drives are four to ten times faster than conventional drives with a control cycle of 100 kHz. This reduces control deviations to one tenth and actively dampens vibrations. The advantages are highest precision and robustness.

The superiority of Triamec Servo-Drive technology is based on two pillars, which are explained in the following sections: minimum dead time or fast control cycle and perfect sensor signals.

Minimization of dead time

Triamec uses the most effective of all control engineering approaches:

- Consistent minimization of the dead time and maximization of the control cycle.

This results in maximum reaction speed: The aim of every control system is to suppress path or position deviations as quickly as possible while at the same time ensuring optimum guidance behavior.

In a conference presentation at the SPS-Drives trade fair in Nuremberg, Nov. 2005, Dr. Kucera illustrated the very positive effects of minimal dead time in a control system. Read the details here. He showed that the reduction of dead time, i.e. the time from the acquisition of the measured variables to the output to the amplifier, brings concrete advantages: The reduction from 260 μs to 25 μs allowed to triple the mechanical bandwidth from 150 to 450 Hz. This corresponds to a tenfold increase in stiffness.

With the high control sampling, resonances up to the kilo-Hertz range can be actively suppressed. This is very useful, because often resonances beyond the useful bandwidth also limit the dynamic range.

The control in Triamec Servo-Drives has five freely programmable universal second-order filter stages. All control parameters and states are stored in SI units in the Servo-Drive and can be displayed and analyzed in real time with up to 100 kHz sampling rate in the TAM System Explorer.

Downloads

Optimal scanning of the sensors

The digital controllers in servo drives depend on measured variables obtained by scanning the analog sensors and subsequent digitization. The well-known sampling theorem of Nyquist and Shannon prescribes that no frequency components above half the sampling frequency may be present in the sampled sensor signal. Otherwise errors, the so-called aliasing, occur, which have a negative effect on the control quality.

Triamec's servo drives meet this requirement by means of complex hardware and software filtering of the signals. The signals are first filtered with passive and active analog filters of higher order and then sampled at a high frequency ("over-sampling"). A second, digital filtering follows in the FPGA in order to spectrally process the input signals for the control.

The success of this technique is a very good, low-noise current and position measurement, which is second to none. In addition to the fast clock frequency, this is the basis for the excellent control quality that Triamec Servo Drives achieve.

Triamec Servo Drives can also be heard: The excellent signal processing leads to a whisper-quiet operation of the axes - audible quality!