High torque meets high speeds

High-speed spindle applications demand exceptional performance at elevated rotational speeds. Continuous high-speed operation causes motor heating with conventional servo drives.

Critical requirements include consistent torque delivery at all speeds, protection of motor windings and bearings, minimal thermal stress on components, and position control capability for positionable spindles.

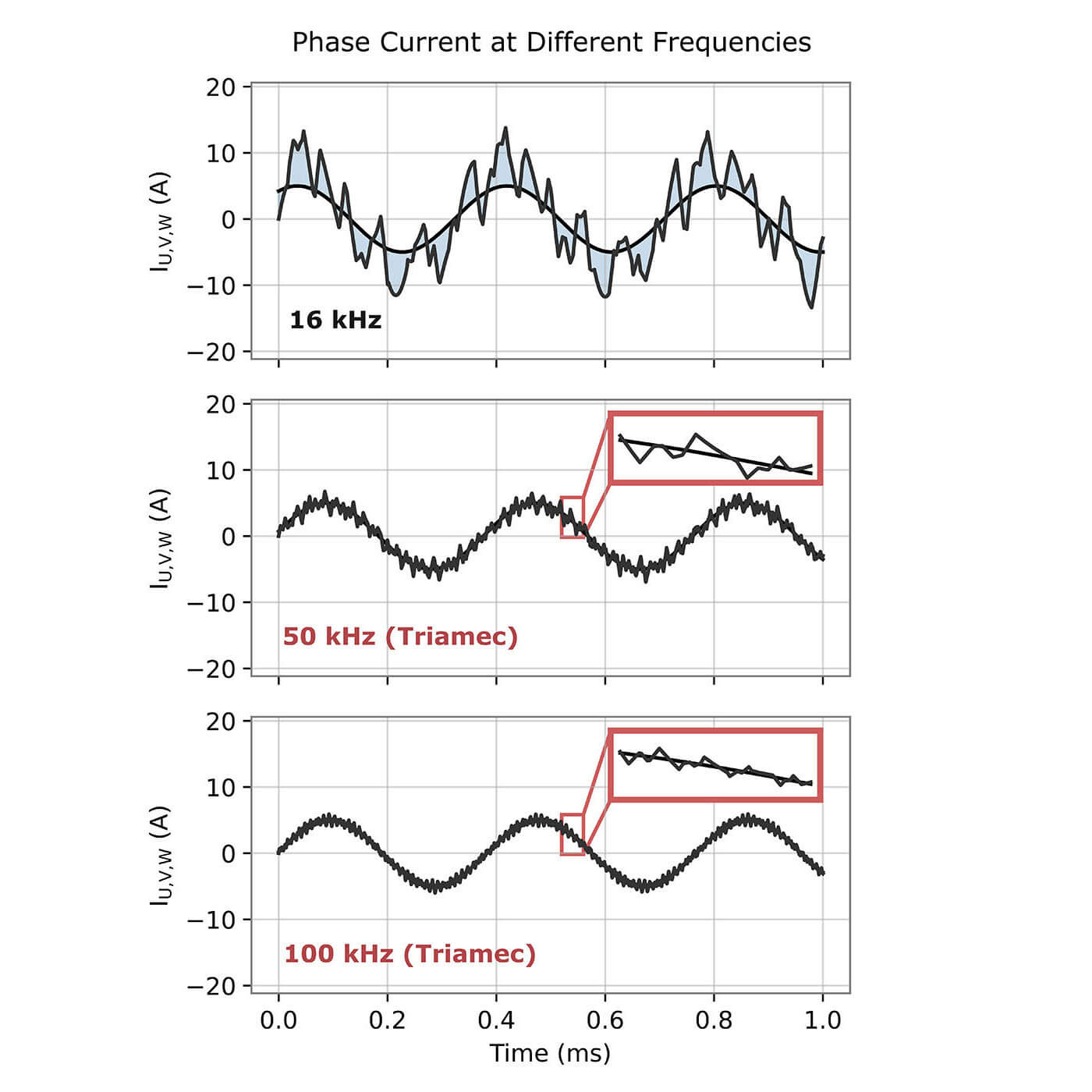

High PWM frequency and filters for more efficient spindles

Triamec servo drives offer selectable PWM frequencies of 50 kHz or 100 kHz. 50 kHz suits most motor types and applications. Switching to 100 kHz PWM provides additional benefits for low-inductance spindle motors, reducing power losses and thermal stress to extend motor and bearing lifetime.

The 100 kHz control loop delivers precise positioning performance across all power ratings, enabling shorter processing times in high-speed spindle applications. Motor-side filters suppress common-mode voltages to protect bearings and windings. T-series filters combine sinus and common-mode filtering for low-inductance motors, while C-series filters provide common-mode protection for all motor types.

Key capabilities

3-level PWM technology

Clean, low-loss sinusoidal commutation even at high rotational speeds

Multi-pole motor support

Higher torque in the same package size at lower cost

Common mode filtering

Protects motor windings and bearings from electrical stress

Reduced thermal stress

Selectable 50 kHz or 100 kHz PWM frequency minimizes power losses and improves efficiency for cooler operation

Positionable spindle capability

Combines high-speed rotation with precise positioning

Adaptable to specific requirements

TAMA programs allow customization

From air-bearing spindles to multi-pole motor applications

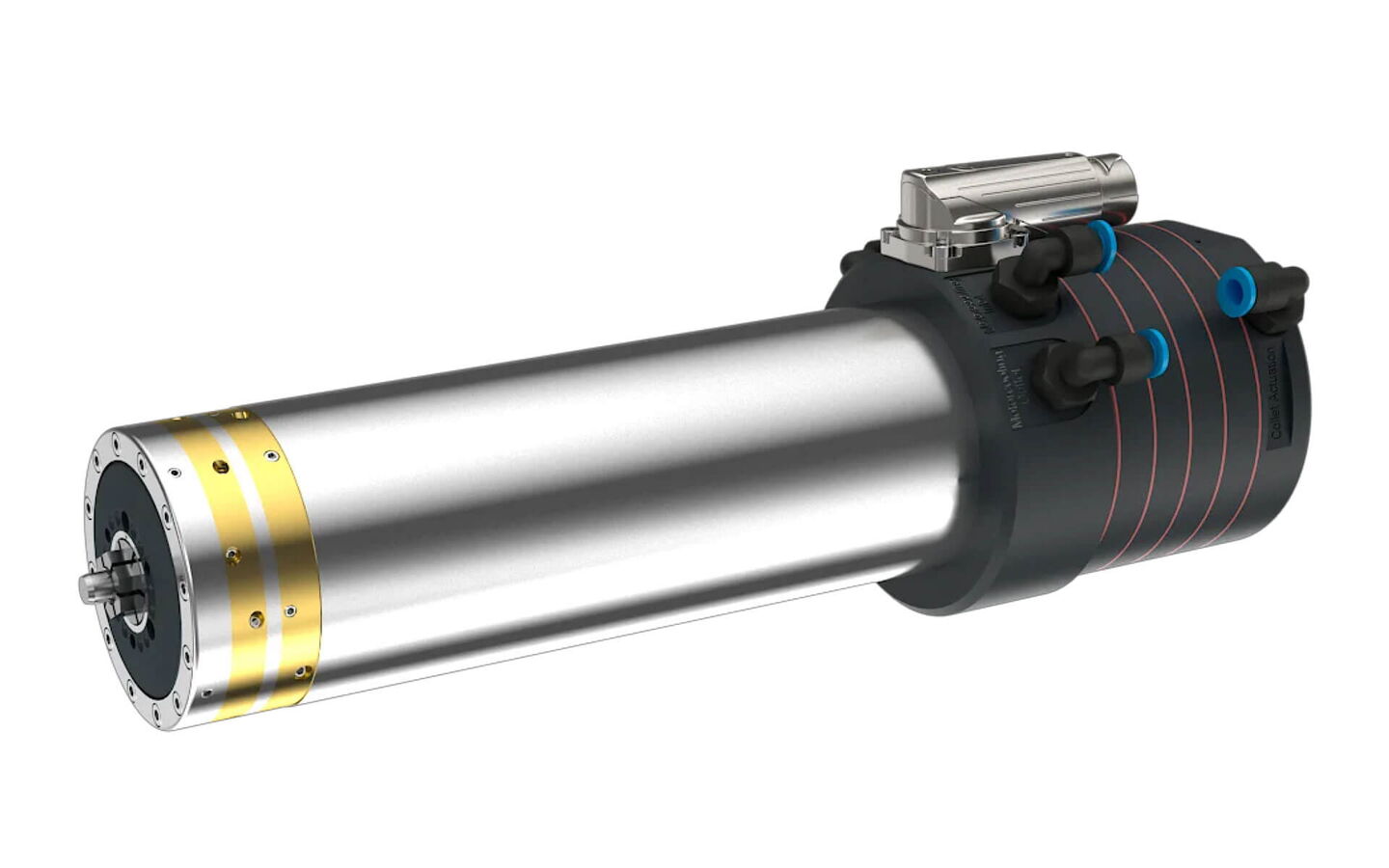

Triamec servo drives enable high-speed spindle applications across precision machining, grinding, milling, and surface finishing. Applications range from positionable high-frequency spindles to air-bearing designs and high-power industrial configurations.

Let's discuss your high-speed spindle application

Our motion control experts understand the unique challenges of high-speed spindle design. Contact us to explore how selectable PWM frequency and motor-side filtering can improve your thermal performance and system reliability.