Nanometer precision meets extreme dynamics

The semiconductor industry demands fastest cycle times, extreme dynamics, and precision in the nanometer range. Wafer inspection, laser processing, die bonding, and wire bonding push motion control to its absolute limits.

Critical requirements include sub-nanometer positioning accuracy, minimal standstill noise, ultra-fast move-and-settle times, and ultra-precise constant-velocity scanning. Air bearing systems and position-synchronized laser triggering add further complexity to already demanding specifications.

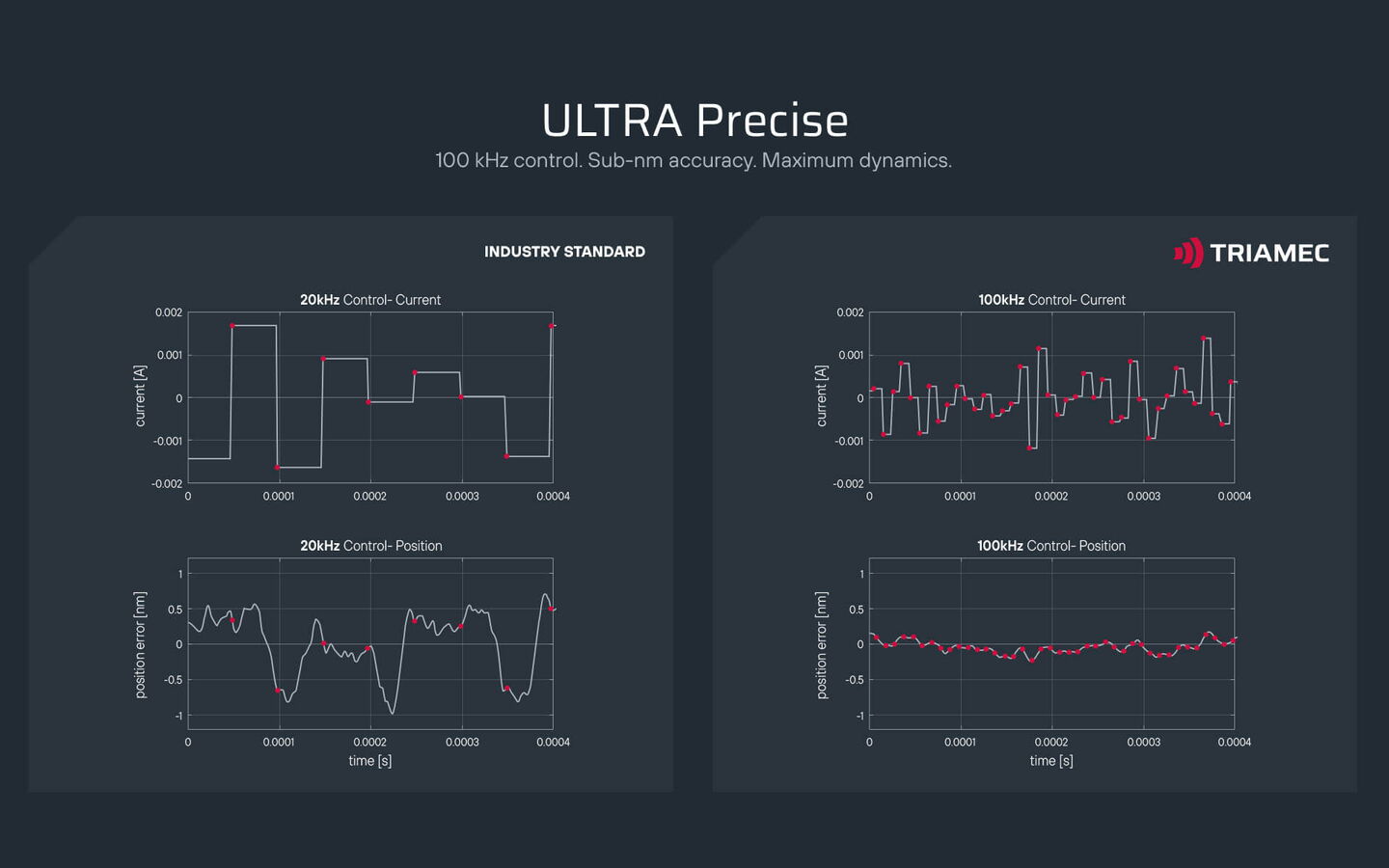

100 kHz control for sub-nanometer precision

Triamec servo drives deliver the precision and dynamics required for semiconductor manufacturing. The 100 kHz control frequency enables minimal settling times, superior scanning accuracy, and lowest standstill noise for stable processes with weakly damped air bearings.

Advanced control algorithms enable sophisticated compensation in 10 kHz to tackle external disturbances while the pulsing unit triggers laser pulses up to 10MHz. This architecture enables deterministic laser triggering synchronized to axis motion.

Key capabilities

Sub-nanometer standstill stability

For critical positioning tasks

Ultra-fast move-and-settle times

For maximum throughput

Unsurpassed

scanning accuracy

For demanding inspection and laser processing

Precise laser triggering

Synchronous to the axis motion with the pulsing unit up to 10 MHz

Advanced MIMO gantry control

Load balancing without controller overhead

V-const scanning and motion profiles

For consistent processing quality

From wafer inspection to laser processing

Triamec servo drives power critical semiconductor manufacturing processes. Applications include wafer inspection, laser processing, die bonding, wire bonding, and hybrid bonding.

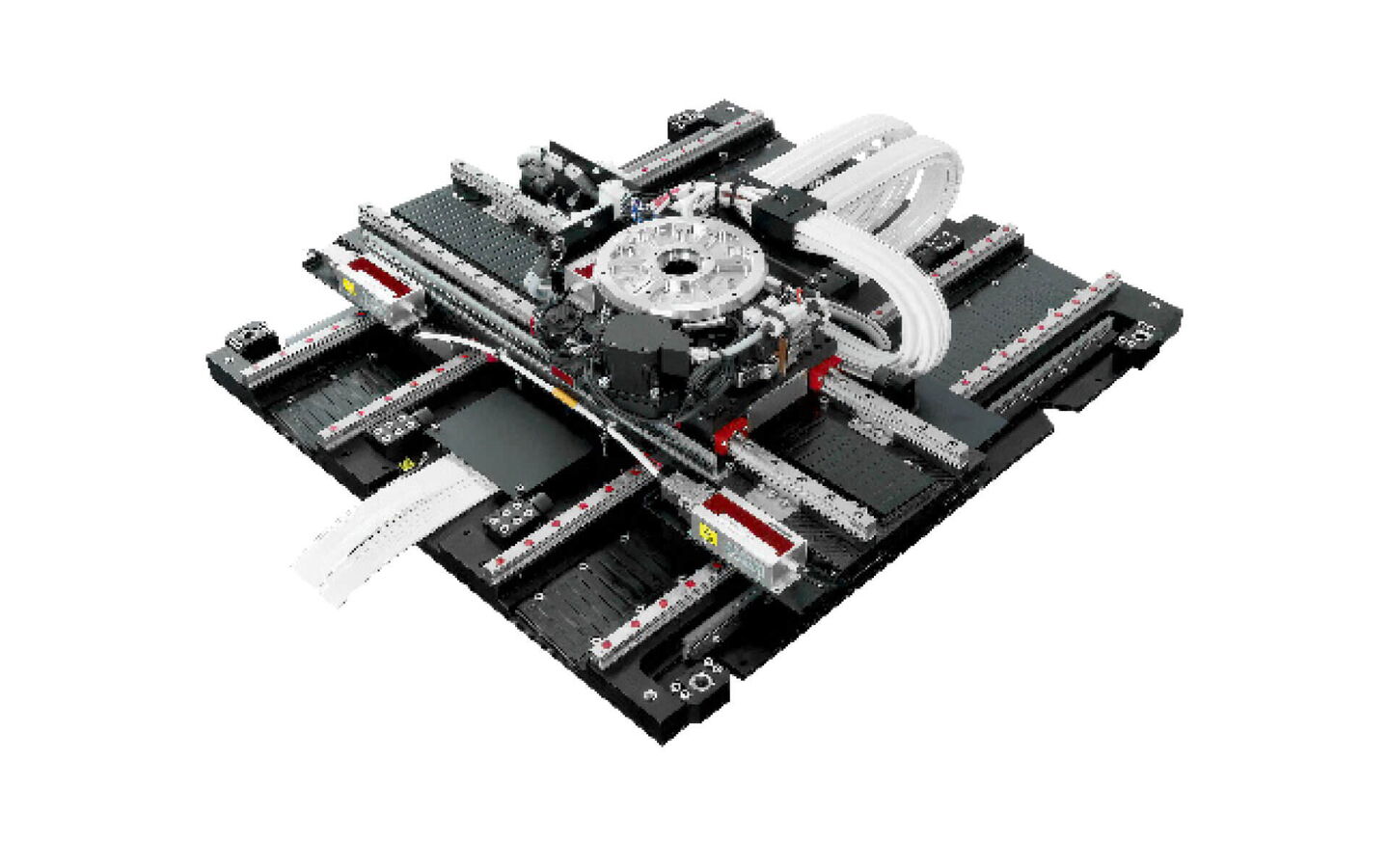

Schneeberger high-precision stages

Challenges

Sub-nanometer positioning with minimal standstill noise and ultra-fast move-and-settle times for semiconductor inspection. External influences such as cable forces require real-time compensation.

Solutions

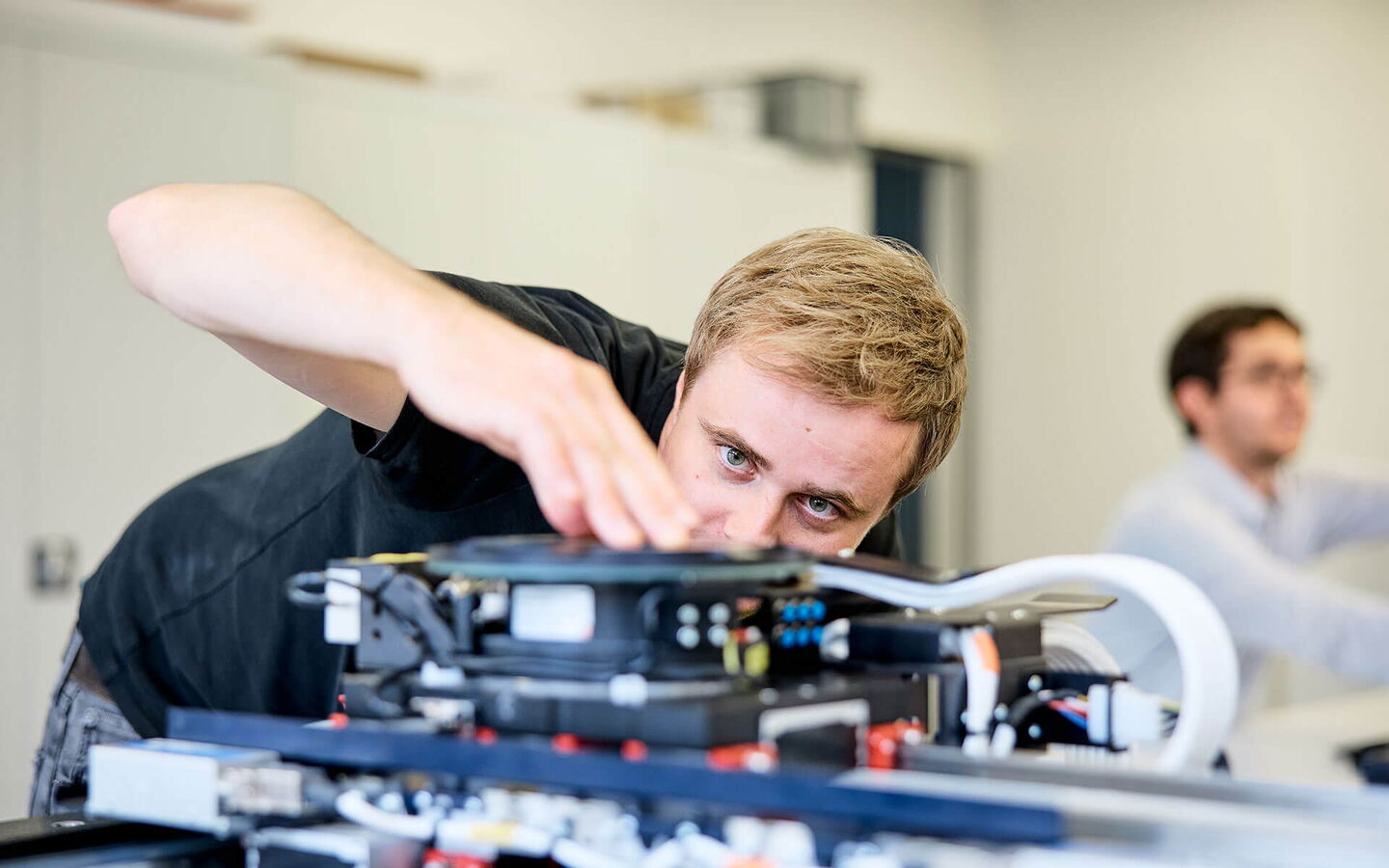

Triamec servo drives connected via Tria-Link with on-drive compensation algorithms.

Result

Gantry wafer stages achieve sub-nanometer positioning accuracy and cycle times required for demanding inspection processes. Improved yield through precise positioning and increased productivity.

Let's discuss your semiconductor application

Our motion control experts understand the unique challenges of wafer inspection and laser processing. Contact us to explore how 100 kHz control technology can improve your positioning accuracy and cycle times.