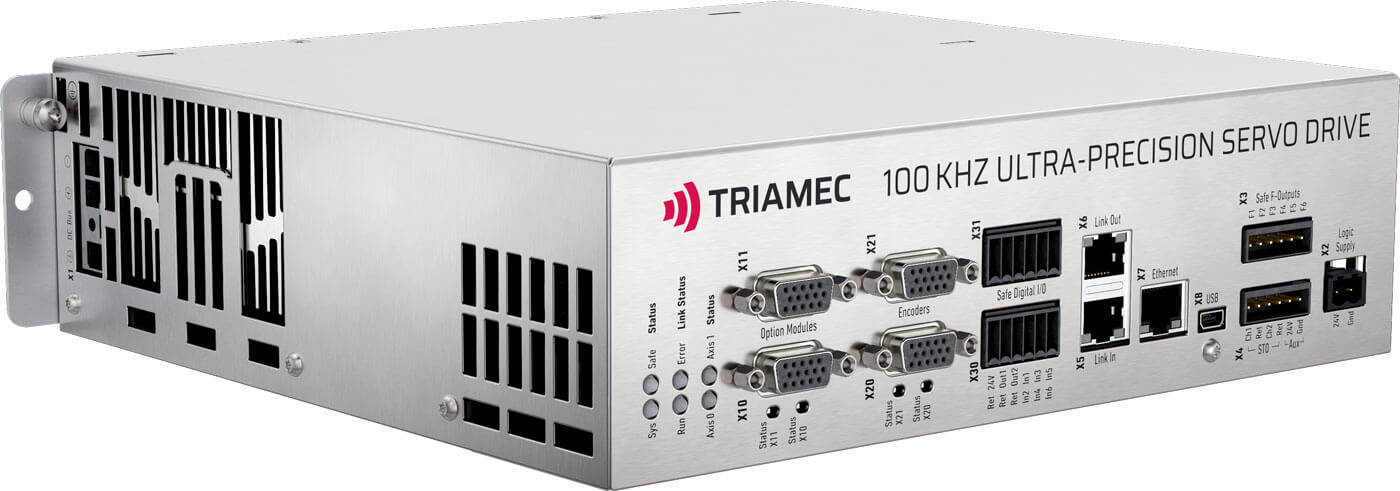

Precision motion control at 100 kHz

Triamec servo drives combine current and position controllers operating synchronously at 100 kHz, delivering the control characteristics required for direct-driven axes in demanding applications. The architecture enables standstill jitter below 0.1 nm, rapid disturbance rejection, and active damping of mechanical resonances.

The TSD series integrates two complete servo drives in one compact housing for space-efficient multi-axis systems. The TSP series features integrated AC power supply and 3-level PWM technology, reducing power dissipation and thermal load from the spindle motor.

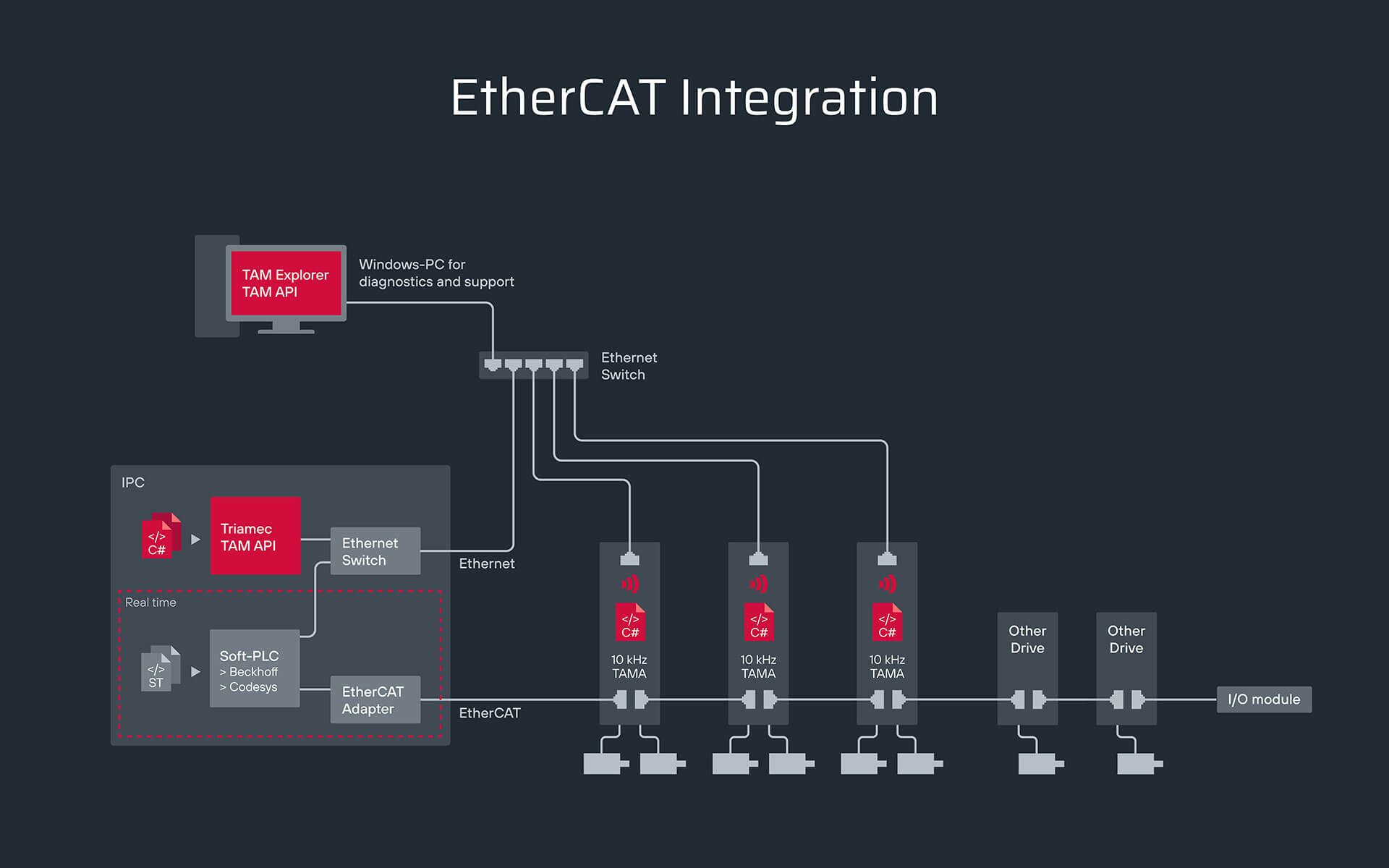

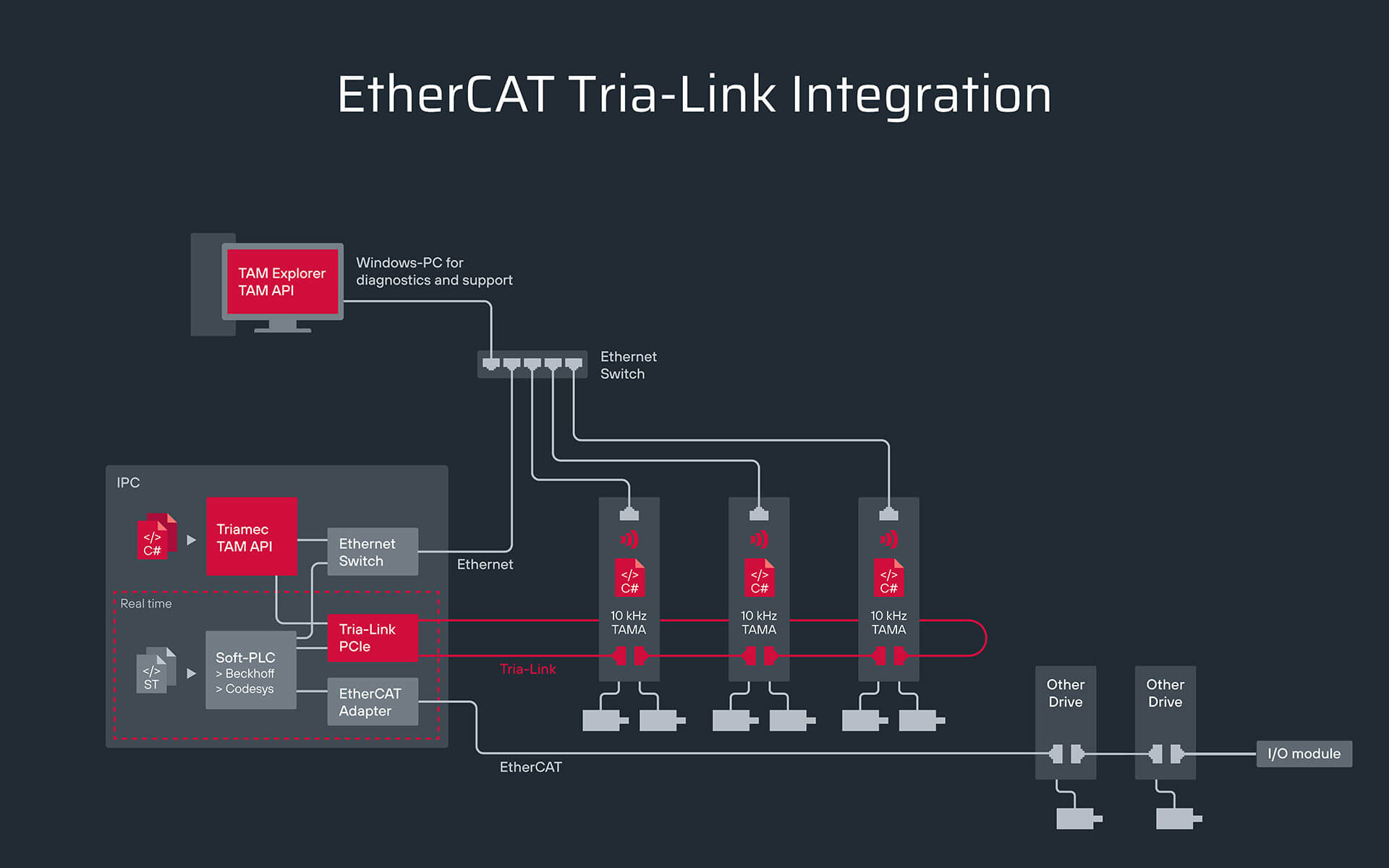

Both series support EtherCAT and Tria-Link fieldbus connectivity, with the option for standalone operation without fieldbus. Commissioning and optimization are performed through auxiliary Ethernet and USB connections, separate from the fieldbus, using TAM System Explorer software for real-time register access at up to 100 kHz sampling rate.

Downloads

Key features

Current and position control at 100 kHz

Path planning 10kHz / axis coupling 10kHz

PID control with 5 filter blocks, SI units

Sin/cos-encoder with 65536-fold interpolation and auto-calibration

Freely programmable in 10 kHz cycle

Redundant safe torque off

Key benefits

Highest stiffness

Quick reaction to disturbances

Precise guidance

Best active damping of resonances

Excellent noise suppression

Common Features

| Supported Motors | 2 and 3 phase synchronous or asynchronous AC, DC |

|---|---|

| Protection | Overtemperature: Drive, motor (KTY83/84, PT100, PT1000, PTC-1K), i2t, overvoltage, overcurrent |

| Safety | Safe Torque Off: SIL3/PLe |

| Position Measurement Analog | sin/cos 1 Vss: 65536-fold interpolation, auto calibration, FIR filtering, 500 kHz cut-off frequency (true interpolation up to 2 MHz, quadrature up to 10 MHz with option module) |

| Position Measurement Incremental |

RS422: max. pulse frequency 10 MHz TTL: max. pulse frequency 2.5 MHz |

| Position Measurement Digital |

EnDat 2.1 [&] 2.2, BiSS B, BiSS C, SSI, Tamagawa, Nikon (encoder types with additional sin/cos signals are recommended – specifications see 'Position Measurement Analog') |

| Sensorless | Sensorless commutation/control, suitable for fast spindles |

| Digital In Per Axis | 6 inputs opt. isolated, 24 V, 2x 300 μs, 4x 1200 μs 4 TTL level general purpose digital inputs per axis on encoder DSub connector |

| Digital Out Per Axis | 2 outputs opt. isolated, 24 V, 1 A |

| Option Modules | 2, each with a D-Sub HD15 Connector, see Hardware Options below |

| Logic Supply | 24 VDC ±10 % at 1.5 A – 2.5 A max. (incl. 2 Option Modules) |

| Fieldbus | EtherCAT 100 Mbps / Tria-Link 200 Mbps. Tria-Link allows for direct transmission of values from one servo drive to others on the same bus. |

| Service interfaces |

USB / Ethernet |

| Programming within the Drive |

Freely programmable with Tama in 10 kHz real-time clock in Microsoft® C#, incl. axis couplings; additional asynchronous task |

| PC Programming | TAM API for Microsoft® .NET Framework, Beckhoff TwinCAT with CNC, Python |

Subject to technical changes.

Product series

TSD series

Two complete servo drives in one housing for compact multi-axis systems. Available in three voltage classes (80 V, 130 V, 350 V) with current ratings from 6 to 15 ARMS per axis. Designed for applications requiring space-efficient packaging and synchronized dual-axis control.

TSP series

High-power servo drives with integrated AC power supply and 3-level 100 kHz PWM technology. The three-level topology significantly reduces power dissipation, minimizing thermal load on the spindle motor and improving overall precision. Suitable for high-speed spindles and applications requiring higher power density.