Highest true running accuracy meets demanding free-form surfaces

Diamond turning, laser machining, and ultra-precision grinding require exceptional concentricity and true running accuracy. Processing demanding free-form surfaces without interpolation errors challenges conventional motion control systems. Fast setpoint rates are essential to maintain surface geometry and to achieve sub-nanometer precision.

Critical requirements include nanometer surface roughness, precise surfaces for optical applications, and perfect multi-axis synchronization. The combination of extreme accuracy demands and complex surface geometries pushes standard servo systems beyond their limits.

Maximum precision and speed with full trajectory flexibility

Triamec's trajectory streaming delivers precalculated moves at up to 50,000 setpoints per second, minimizing interpolation errors to preserve the exact geometry of complex free-form surfaces. This high setpoint rate enables precalculated feedforward currents and synchronized process control.

Combined with 100 kHz position control, this architecture achieves nanometer surface roughness and optical-quality finishes in diamond turning and precision grinding applications.

Key capabilities

50 kHz trajectory streaming

Precalculated moves at up to 50,000 setpoints per second

Eliminates interpolation errors

Preserves exact geometry of complex free-form

Precalculated feedforward currents

Optimized current profiles for reduced following errors

Real-time where it belongs

Standard PC or offline calculation while drives handle real-time control

Nanometer surface roughness

Ultimate accuracy enables optical-quality surface finishes in diamond turning

Laser machining precision

Synchronized control enables precise laser processing of complex geometries

From micro-optics to eyeglass lenses

Triamec servo drives enable ultra-precision machining applications from diamond turning of phone camera lenses to high-volume production of progressive eyeglass lenses. Trajectory streaming technology delivers optical-quality surface finishes across diverse manufacturing requirements.

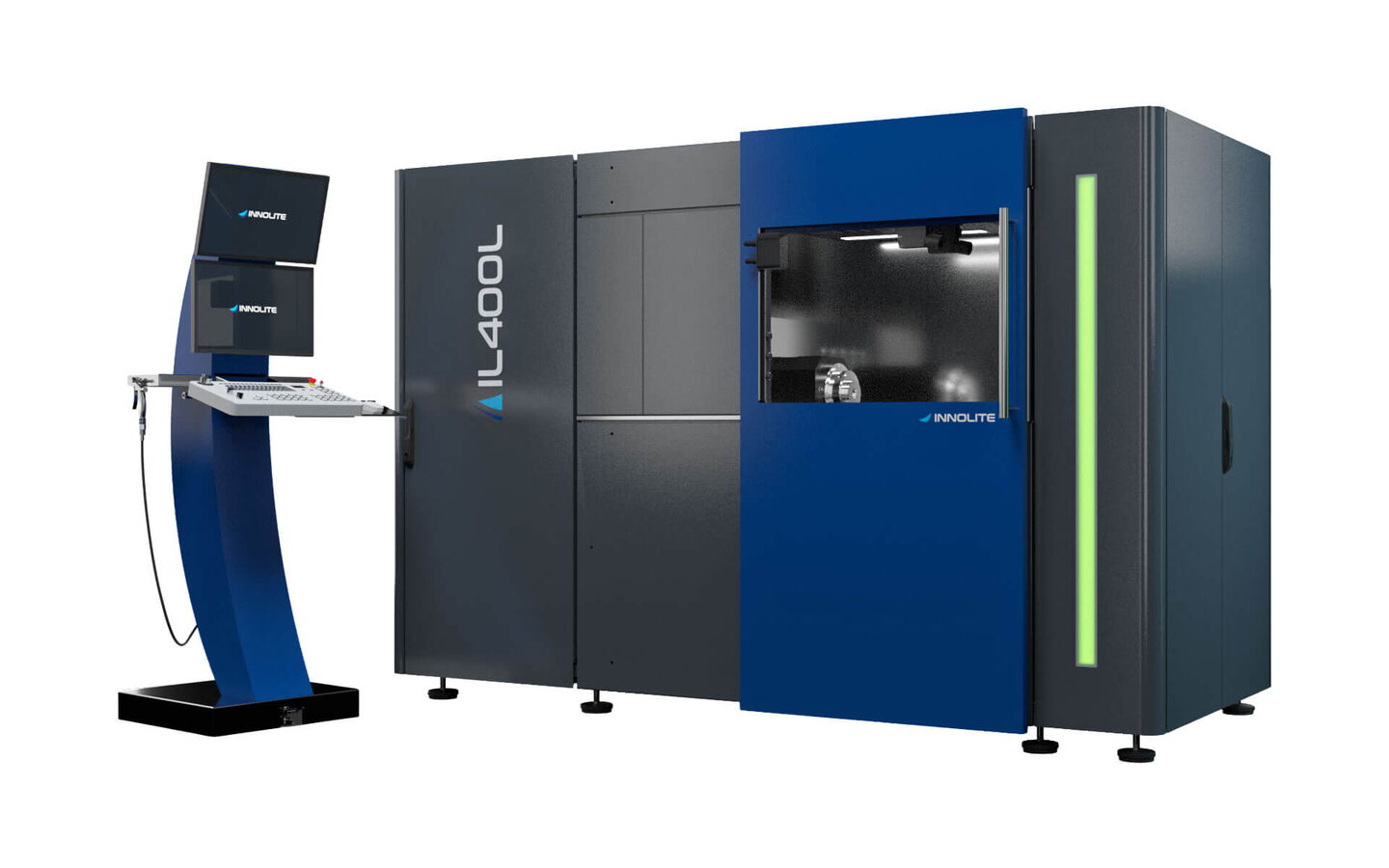

Ultra-Precision Lathe – Innolite

Challenges

Highest geometric accuracy and optical-quality surface finishes for small to medium components.

Solutions

Triamec servo drives with DirectDrive3D trajectory streaming. Offline precalculation delivers 10,000 setpoints per second across all interpolating axes. Integrated active machine bed decoupling and dynamic error compensation.

Result

Innolite's IL400 ultra-precision lathe platform achieves nanometer-level accuracy for small and medium-sized components. Compact base axis design combined with active machine bed decoupling and real-time compensation of dynamic following errors delivers the surface finishes required for optical manufacturing.

Let's discuss your ultra-precision application

Our motion control experts understand the unique challenges of diamond turning, optical manufacturing, and ultra-precision grinding. Contact us to explore how 50 kHz trajectory streaming can improve your surface quality and form accuracy.