Manufacturing process

Semi-finished products are manufactured by our partners in Switzerland. Final assembly and testing take place at Triamec headquarters in Baar, where each servo drive undergoes comprehensive functional and thermal validation before shipment.

ISO 9001 certification ensures consistent quality standards throughout the manufacturing process.

Downloads

Quality Assurance

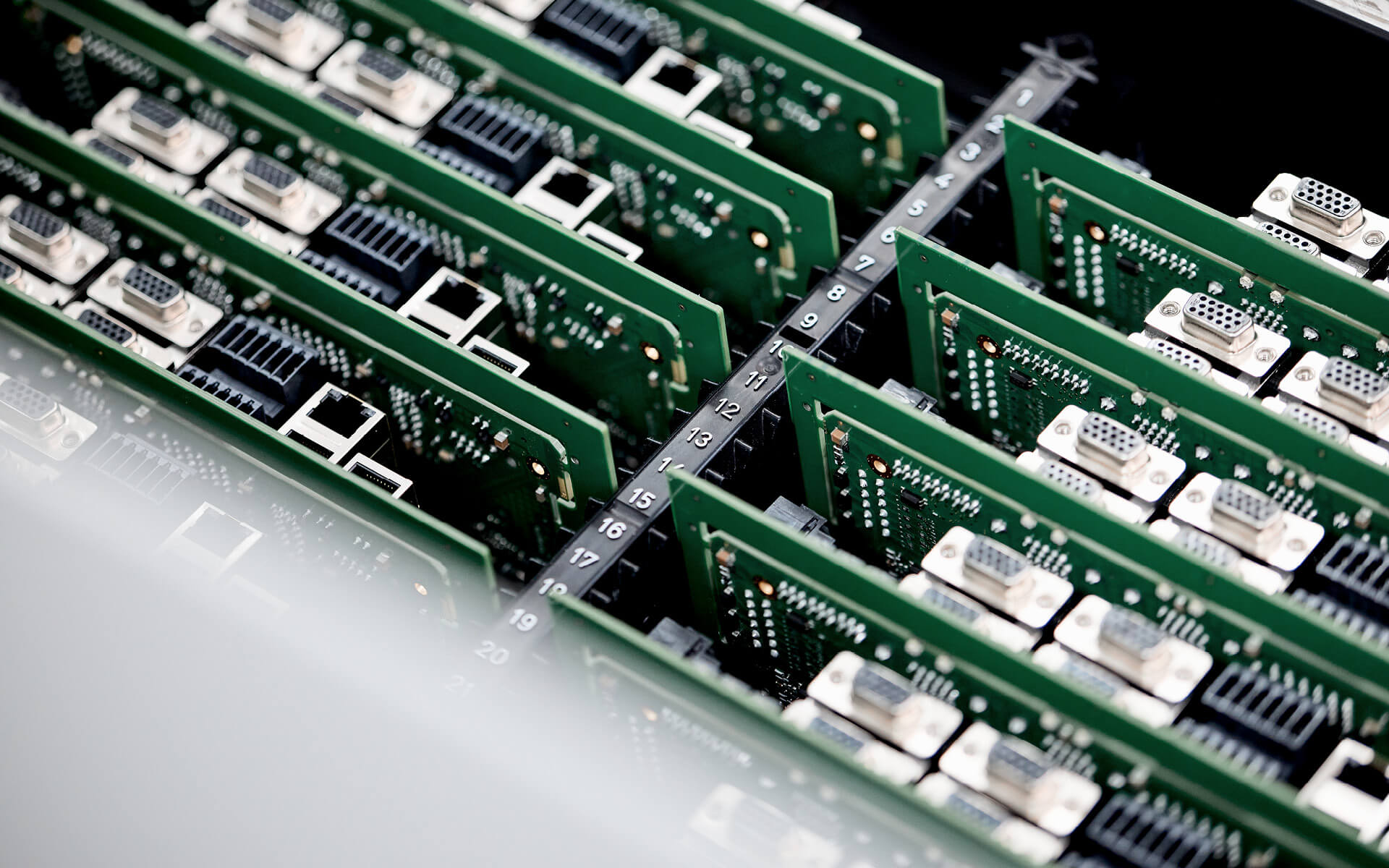

Functional testing

Custom-built test racks validate all drive functions. Each unit undergoes comprehensive testing including digital and analog I/O, encoder interfaces (with 2-phase DDS evaluation for bandwidth, filter characteristics, and channel matching), safety systems, and brake chopper operation. Burn-in testing with peak and continuous current loads verifies performance, while overcurrent protection and Safe Torque Off (STO) validation ensure proper channel separation and shutdown behavior across all operating quadrants.

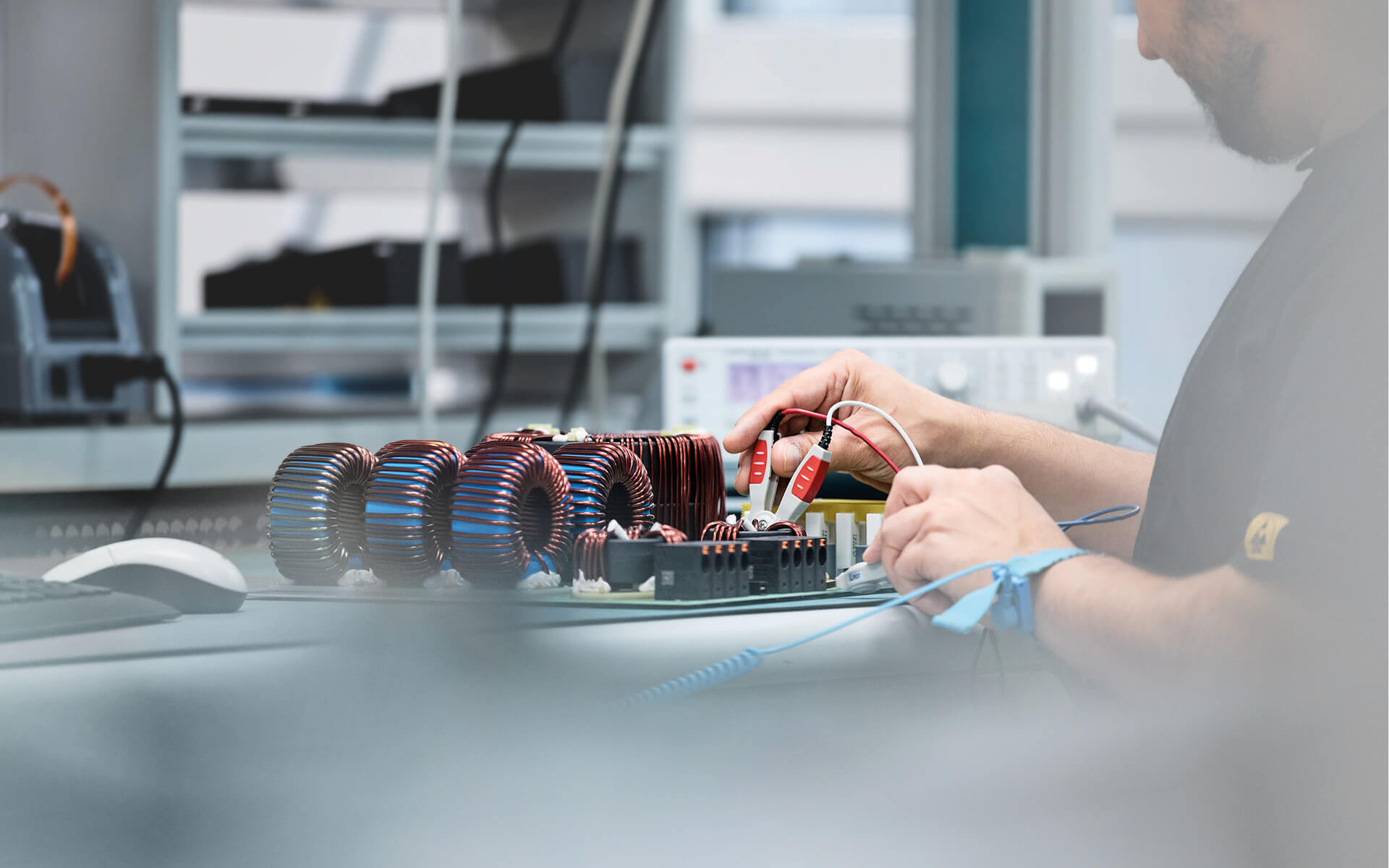

Thermal and EMC testing

Thermal testing verifies performance under continuous and peak loads across all quadrants, including thermal shutdown behavior. In-house EMC equipment including network simulation and spectrum analyzers measures conducted interference. Insulation testing includes partial discharge measurement below 5 pC and isolation measurement up to 5 TΩ.

Software validation

Dedicated test infrastructure executes over 1,000 automated regression tests with continuous expansion. All development activities are documented in version control systems (Subversion), ensuring complete traceability throughout the product lifecycle.