Precision and dynamics for demanding machining

High-speed CNC milling, turning, and micro-machining require extraordinary precision and surface quality. Tool and component wear during metallic surface machining reduces productivity and increases operating costs.

Critical requirements include rapid acceleration and deceleration cycles, high stiffness for precise trajectory following, and continuous process monitoring. Multi-axis coordination and resonance damping add further complexity to already demanding specifications.

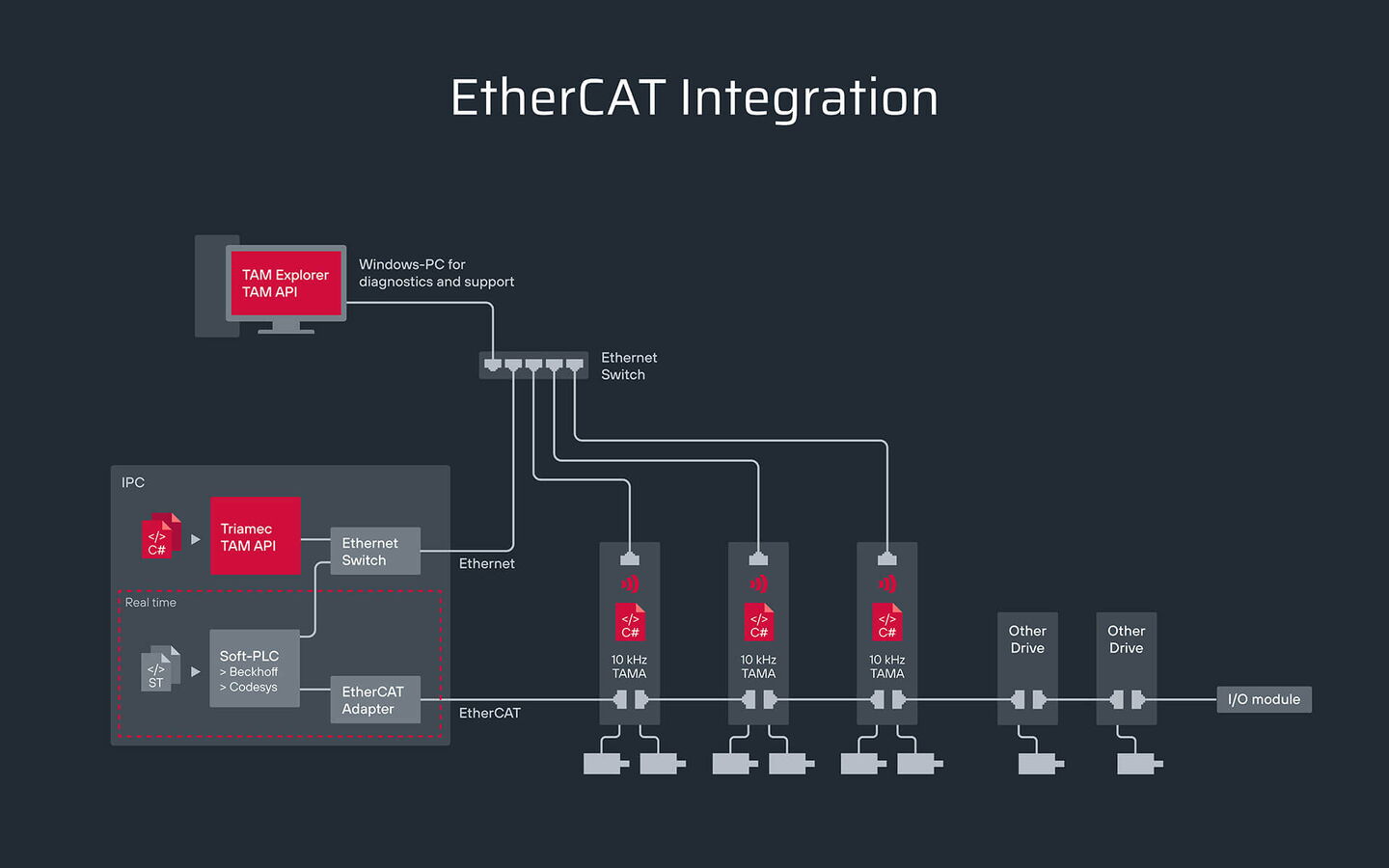

Maximum precision with seamless EtherCAT integration

Triamec servo drives are native EtherCAT slaves, enabling direct communication with Beckhoff TwinCAT and standard PLCs. Control algorithms execute on the servo drives at 100 kHz, delivering high stiffness and precise trajectory following with minimal deadtime.

Motor-side filters extend the lifetime of tools and components during demanding metallic machining operations. Full parameter access and on-drive programming enable continuous process monitoring and application-specific diagnostics.

Key capabilities

100 kHz control frequency

For high stiffness, precise trajectory execution and superior surface quality

Seamless EtherCAT integration

Native EtherCAT slave for direct communication with Beckhoff TwinCAT and standard PLCs

Ideal for direct drive axes

100 kHz control enables active damping of resonances

Adaptable to specific requirements

TAMA programs allow customization thanks to full access to signals and registers

Motor-side filtering

T- series and C-series filters extend lifetime of tools and components

Continuous process and equipment monitoring

Specific analysis, including sensor evaluation, can be programmed directly on the servo drives

From micro-machining to high-precision CNC

Triamec servo drives enable CNC milling and turning centers, micro-machining systems, and precision tooling for medical device manufacturing and watchmaking applications.

Precitrame K5

Challenges

Micro-machining requires equipment scaled to match the parts being produced. Higher precision and faster dynamics than standard operations are essential, while metallic surfaces accelerate tool and component wear.

Solutions

Triamec TSD130 servo drives connected via EtherCAT to Beckhoff controller and Precitrame Machine Manager HMI. Motor-side filter TFS-T extends component lifetime.

Result

The K5 micro-machining center delivers sub-micrometer accuracy for medical device and watchmaking applications. Compact footprint reduces floor space and energy consumption while maintaining high-speed operation and precise trajectory following.

Willemin-Macodel 701S

Challenges

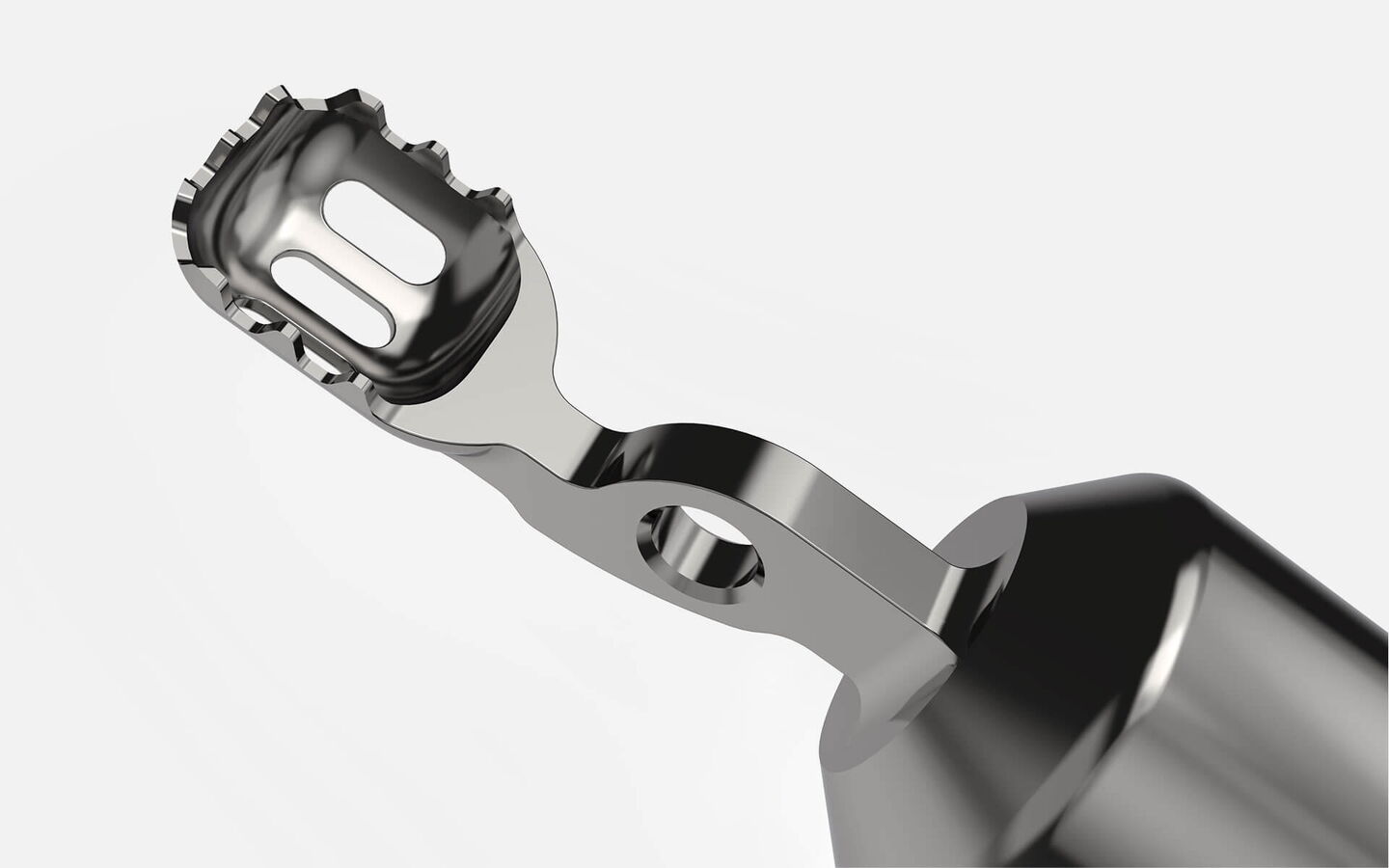

The tripod architecture delivers identical high dynamics across all three direct-drive axes. Premature wear of tools and components becomes more critical with smaller metallic workpieces. The 80,000 rpm high-speed spindle requires high standstill torque for tapping and tool tightening. Measurements must be possible without touch probe.

Solutions

Triamec servo drives with motor-side filter, connected via Tria-Link to the 701S machine controller and Beckhoff GUI. The servo drives enable direct position measurement for the DMS (Direct Measurement System) without requiring additional touch probes.

Result

The 701S machining center leverages the dynamic control and rigidity of linear delta parallel kinematics. It delivers sub-micrometer precision and high dynamics for watchmaking and micro-machining applications with a small footprint and low power consumption. The DMS technology, developed by Willemin-Macodel, is a high-resolution 3D measuring solution that uses the machine's main axes to reference parts and measure shape and dimensions directly.

Let's discuss your machine tool application

Our motion control experts understand the unique challenges of CNC milling, turning, and micro-machining. Contact us to explore how 100 kHz control technology and seamless EtherCAT integration can improve your surface quality and cycle times.